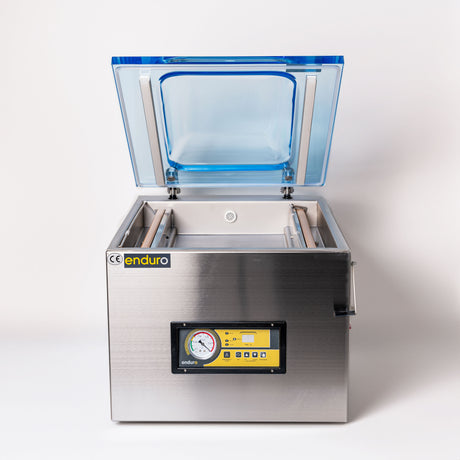

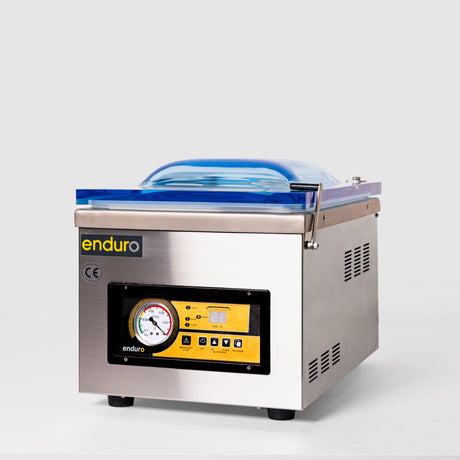

Vacuum Packing Machines

Reduce Waste Increase Flexibility

Save time & reduce cost

-

Like to Discuss a Deal?

Contact us Now

Why Enduro

A vacuum sealer you can depend on

When you run a busy operation, you want the peace of mind that your vacuum packing isn’t going to slow things down. Enduro’s range of benchtop and inline packaging machines are world-class in build quality and function. Across New Zealand, businesses of all kinds are relying on their Enduro vacuum sealers to produce a finished product their customers will keep buying. With warranty, service and support, Enduro is your ongoing vacuum packaging partner.

Compatibility with the Enduro vacuum range

You’ll find information about compatibility on individual product pages and in any available product sheets. If you’re still unsure whether a specific machine is fit for your purpose, get in touch with us or use our quote tool to get started.

Getting set up with your vacuum packer

We provide detailed documentation with machines. Installed, inline machines will require a bit more time and consideration as they need to be integrated into your existing operation. A benchtop machine is a quicker process, although there are still some steps to follow:

- Unbox the machine from its packaging, making sure all parts are to hand.

- Place the machine on a stable flat surface - ideally the area you’ll be using the packer.

- Ensure the space is big enough for your consumable vacuum packaging and the machine to all be comfortably used.

- Keep the area free of water or moisture (outside of the contents you’re packing)

- Review your specific packer’s manual to learn safe, correct operation.

- Plug in, switch on and run a test. You may wish to try first without a bag, then load a bag or pouch for a live test. Make sure you’ve placed the consumables correctly in the machine.

- Make sure the open end of the bag is in the machine, flat over the sealing bar.

- Start the process per the instructions provided with your specific model. You may need to adjust settings to suit.

Common mistakes to avoid with vacuum packing

While Enduro’s range is designed to be intuitive, there are some useful tidbits to know about. Try not to overfill the vacuum bag as this can prevent the bag from being sealed properly. Give yourself some room at the end of the bag to help achieve a good seal.

You might also want to consider cleaning the sealing area - in a food packing situation, there’s plenty of opportunity for liquids and food residue to prevent a seal’s integrity.

Give the machine a regular clean and check key elements like the sealing bar and gaskets. Enduro can help provide support if you’re not sure about the performance of your machine at any point.

Not just for commercial usage

We don’t just sell to businesses - you can easily purchase on our website for any home or hobby needs such as storing game, preserves, fruits or doing your own meal prep. You may also want to use a benchtop vacuum packer for compact storage of smaller items. If you’re not sure what option will suit your needs, get in touch with our team.